Galleria Romanelli, Model Mold

Once I had completed the bas relief, it was allowed to dry for a few days, and I started on the project of Bernini's Santa Theresa. Once it was dry enough to become slightly hard, but not to the point of cracking we decided to make a mold of it. There were two options available, one is to make a mold from silicone, the silicone sitting inside a harder plaster or carbon fiber mold, or the other method is with whats was called "vinyle" or some type of vinyl type polymer. The silicon is more expensive, but captures the modle with higher accuracy. The vinyl is reuseable and cheaper but not quite as accurate. For my bas relief I chose to use the reuseable vinyl.

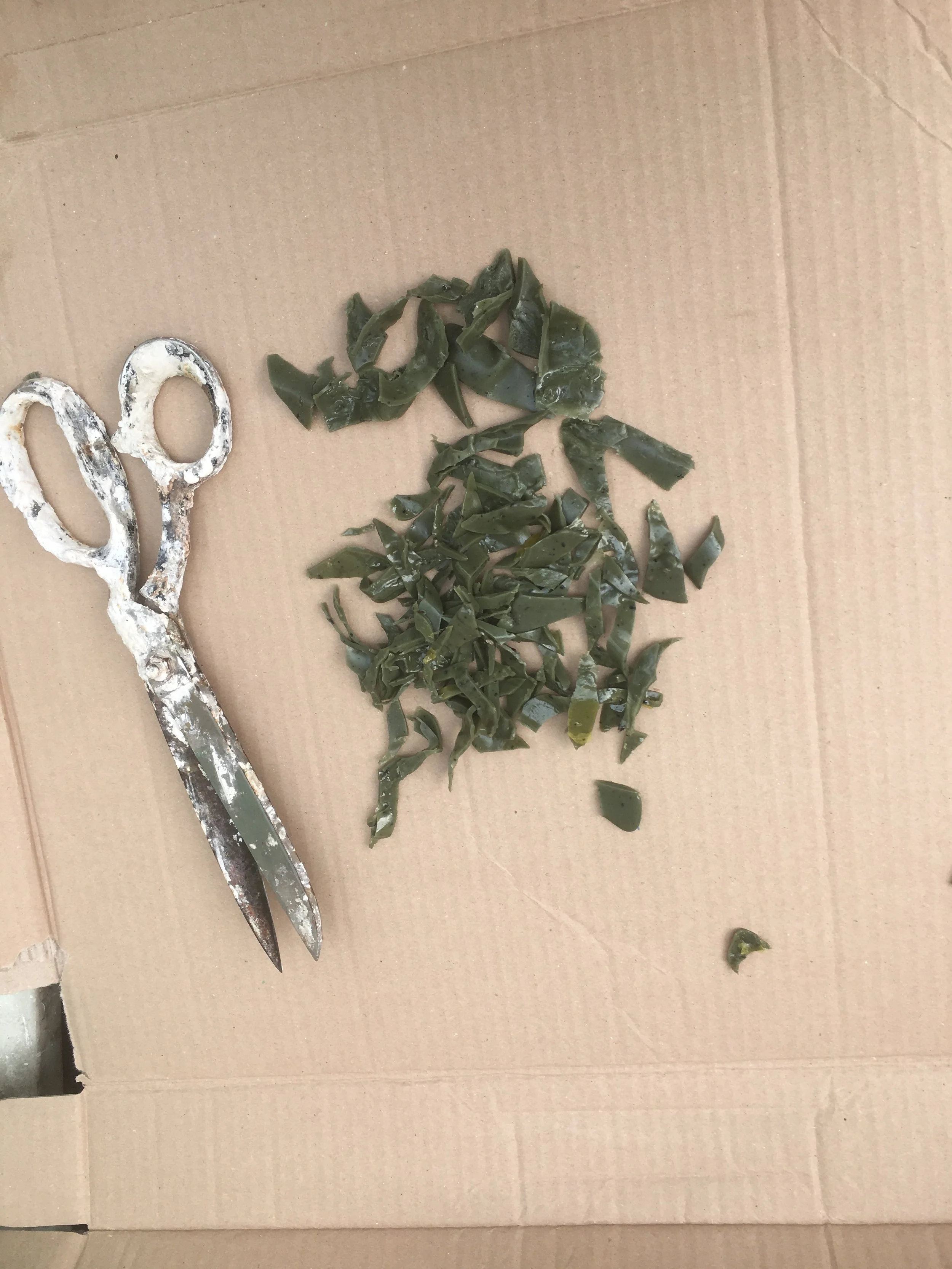

Here is the vinyl sheet left over from someones previous mold.

The Vinyl sheet must then be cut into small pieces. These peices are then placed into a kettle and heated on high heat until they start to liquefy. It is important to keep stirring the kettle as if the vinyl is not stirred, the portion on the bottom will stick and start to burn. It also gives off strong fumes when heating. Once the entire kettle is thoroughly melted, it is then poured onto the model. It should be first poured into the deepest portions of the model, and a brush can be used to get rid of air bubbles because of the high heat of the vinyl liquid. Once the vinyl has been poured over the entire model, it is allowed to harden, then plaster is poured over the vinyl and model, forming a hard shell for the mold to rest in. Before pouring the plaster it may be neccessary to create a clay "dam" around the area to be cast. After the cast dries this clay dam can be removed.

The vinyl is cut into small peices to help with melting

It is important to constantly stir the mixture.

The vinyl is now ready to pour

A clay dam is built to contain the plaster pour

The vinyl poured and cooled.

Plaster case built up and hardening.

The mold is removed from the model, and is ready for use.